A machine that can make anything. It sounds like the future, but it is here now. However, the prospect of making just about anything comes with a cost.

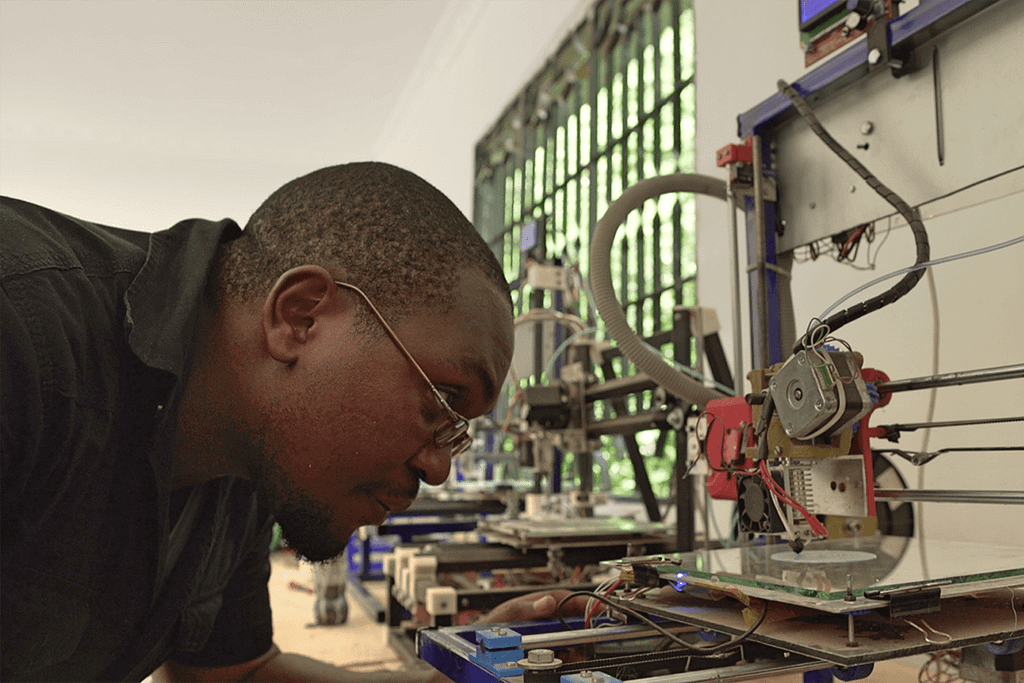

3D printing is a method of creating materials using an extruder to bring digital designs to life. It’s a technology with immense potential, but for every opportunity it presents, there are questions about sustainability and social responsibility. This is where Reflow Filament comes in. Reflow Filament is a company that creates a sustainable source of filament, the “ink” that fuels 3D printers, by using recycled plastic. But environmental sustainability is not its sole focus. Reflow Filament is also a social enterprise making economic sustainability a priority for those involved in the industry — from the waste collectors that gather the plastic that will become recycled ink, to the engineers using filament to produce everything and anything from prosthetic limbs to art. “Our goal is to preempt growth that is already exploding to make sure that the 3D Printing industry is sustainable and inclusive from the get-go,” explains Ronan Hayes, co-founder of Reflow Filament.

Reflow Filament: Empowering Communities Through Sustainability. was originally published in Berkeley Master of Engineering on Medium, where people are continuing the conversation by highlighting and responding to this story.