By Jack Yue, MEng ’23 (ME/Product Development)

This op-ed is recognized as an Honorable Mention in the annual Berkeley MEng op-ed contest and part of a series from E295: Communications for Engineering Leaders. In this course, Master of Engineering students were challenged to communicate a topic they found interesting to a broad audience of technical and non-technical readers. As an opinion piece, the views shared here are neither an expression of nor endorsed by UC Berkeley or the Fung Institute.

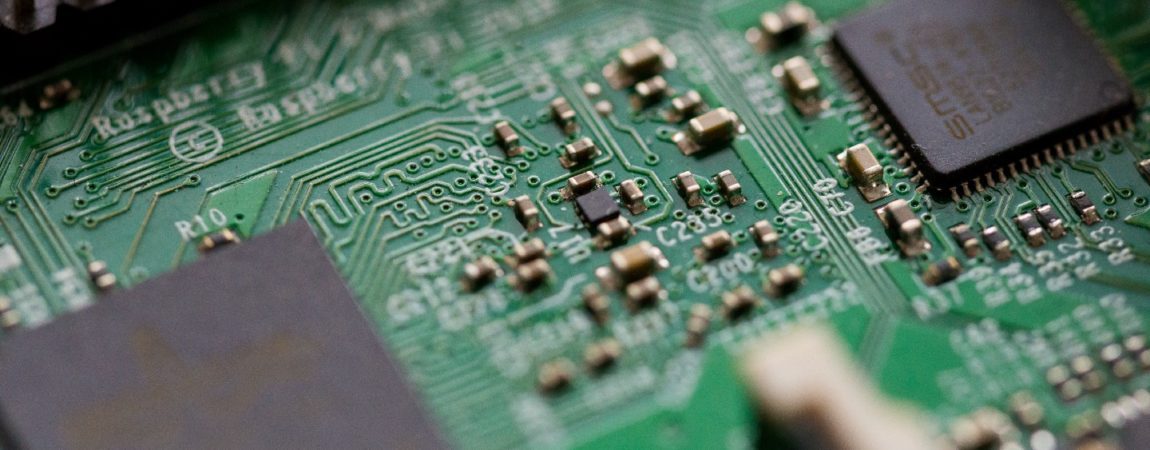

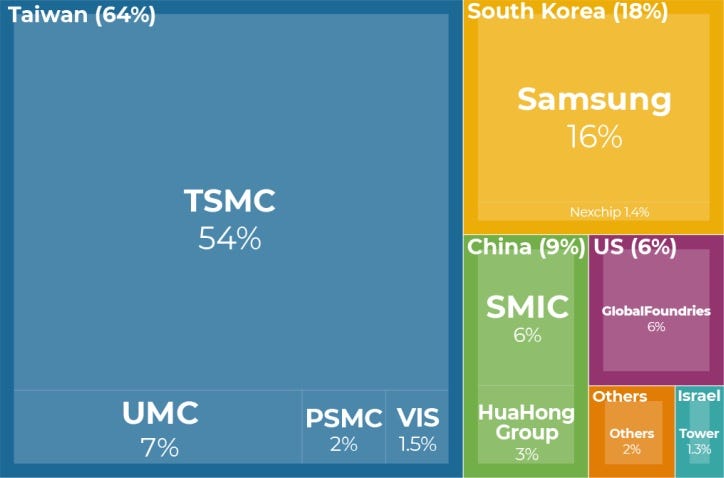

“While the demand for semiconductors is at an all-time high as societies recover from Covid-19, the supply remains heavily restricted.”To address these concerns, the Biden administration signed the CHIPS and Science Act in 2022 to inject approximately $280 billion into the semiconductor research and manufacturing sector in the United States. (Jean-Pierre, 2022) This pledge is estimated to create a historical number of manufacturing jobs in the US while creating more regional technology hubs. Since 2021, 642,000 manufacturing jobs have been created in the United States. (Jean-Pierre, 2022) Companies are beginning to invest in the United States again, and the number of new manufacturing facilities has increased by 116% in the past year alone. This increase would dramatically lower the reliance on importing these advanced chips abroad and allow the United States to control the technical trade secrets that go into creating these chips. However, even though this is a great start for bringing more of the technology back home and decreasing reliance abroad, this is not sufficient to solve the critical issues of developing these complex semiconductor chips. The main issue with producing these chips is that the level of expertise is still highly concentrated abroad. (Lee, 2010) The technical knowledge of how to produce and manufacture these chips is still heavily safeguarded since these are commercial products, and there has not been significant support for students in the US to pursue a career in this industry in the past compared to Asian countries.

Op-ed: The United States semiconductor talent shortage was originally published in Berkeley Master of Engineering on Medium, where people are continuing the conversation by highlighting and responding to this story.