By Michael Ji Wang

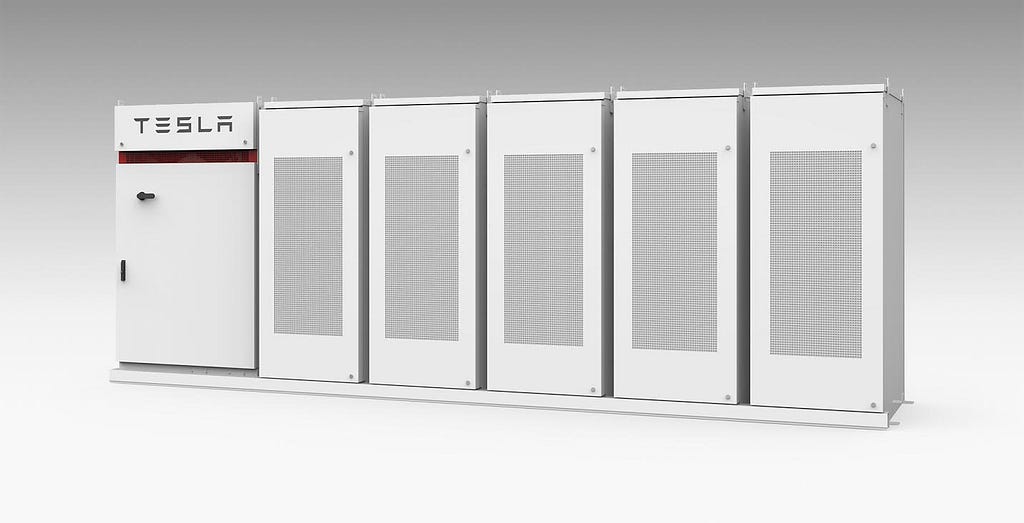

Michael graduated from UC Berkeley with a Master’s degree in Material Science Engineering in 2014, and started working at Tesla the same year at Palo Alto, California. Earlier this year Tesla Motors Inc. filed with the US Securities & Exchange Commission to officially change its name to Tesla Inc. In part this change reflected the fact that Tesla has begun to refashion itself from selling electric cars to establishing itself as a sustainable energy empire. Tesla’s product offerings now include the Model S, X, 3, solar panels, solar roofing, powerwall (Tesla home battery), and commercial grade energy storage products.

As crazy as it might sound, all this had already been envisioned in Elon Musk’s “secret master plan” written 10 years ago. In that plan, he laid out a future where autonomous cars roam the streets and homes are powered by the sun. His dream is fast becoming a reality.As a real-life Tony Stark, Elon Musk is known for his affinity for challenging conventional wisdom. He has shaped his companies in his own image: innovative, agile and unafraid to take risks. In multiple interviews, he outlined his thinking methodology, “I think it’s important to reason from first principles rather than by analogy.” Indeed, Tesla has recruited and trained with the “reasoning by first principles” approach, a mode of inquiry that relentlessly pursues the foundations of a problem. I’ve utilized this method in many challenging and unfamiliar situations in my 3 year tenure here, in the fast and furious world of Tesla. When I first joined Tesla in September 2014, we were just about to launch a dual motor all-wheel drive configurations to the Model S, P85D. This option would give the car supercar acceleration — achieving 0 to 60mph in 3.2 seconds — and would become the fastest four-door production car ever made. The pressure was intense on all teams to execute and deliver, but with last minute design tweaks, we were unsure if we could ramp up the manufacturing capacity at one of the major suppliers supporting the dual motors.

On a day to day basis, there are fresh challenges of supplier quality issues, logistical delays, payment conflicts, and even contractual disagreements just to name a few. Tesla does not provide guidelines or rulebooks on how to deal with these issues. There are no formal trainings, and everything you learn, you learn on the job.

Being on the Frontier of Tesla’s Electric Revolution was originally published in Berkeley Master of Engineering on Medium, where people are continuing the conversation by highlighting and responding to this story.