Team: Alex Wolcott (BIOE), Martin Banet-Rivet (ME), Pablo Amo (ME), Ruobin Liu (ME)

Advisors: Boris Rubinsky (ME), Gideon Ukpai (ME)

The organ shortage for transplants is a growing problem all over the world. Bioprinting could be a solution to this however current attempts at 3-D printing biological materials are encumbered by the slow rate of the process and the “soft” nature of the material. Previous “successes” have only yielded objects no larger than a dime, as both the tendency for these materials to collapse and the need to preserve any cells limit the 3-D printing process. 22 people die waiting for organ transplant per day in the US.

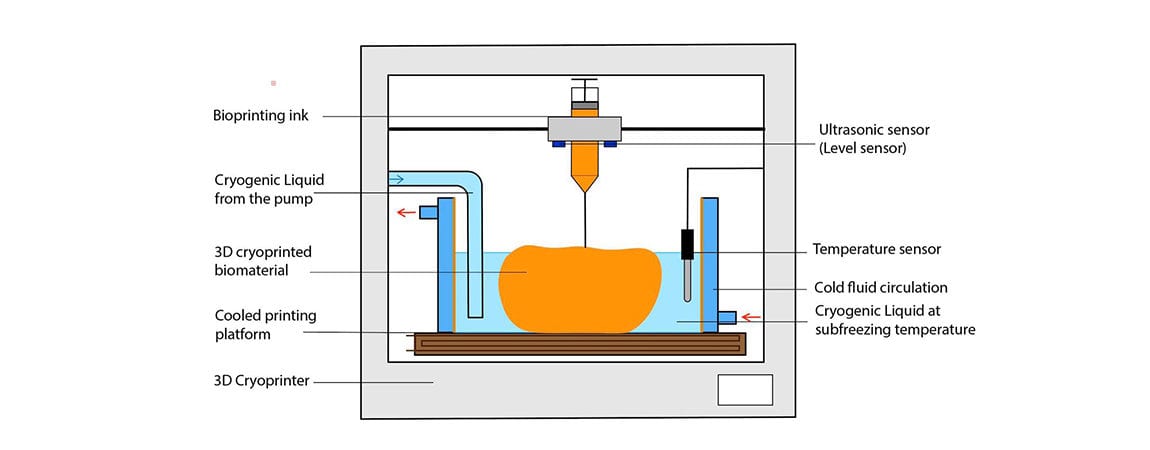

We have designed a level-controlled cooling bath to precisely freeze biomaterials as they are printed. This provides the bioink with the structural integrity needed to support larger structures and ensures living cellular material is preserved. This new approach allows for larger printed structures than previously possible. The bath is designed to maintain a constant temperature by flowing cooling liquid within its walls.

Ultrasound sensors and a thermistor are used to control in real-time the level and the temperature of the cryogenic fluid.

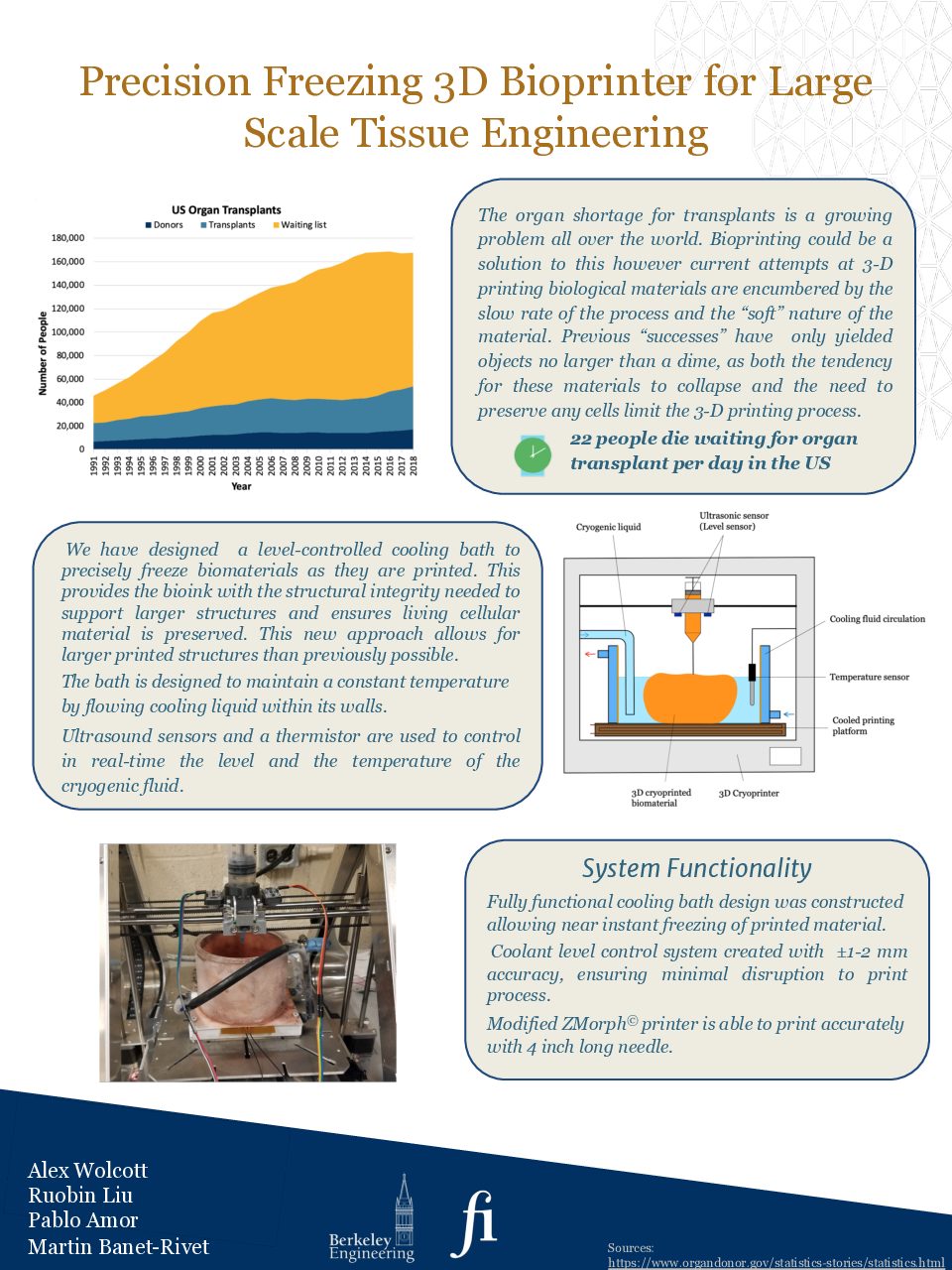

Fully functional cooling bath design was constructed allowing near instant freezing of printed material. Coolant level control system created with ±1-2 mm accuracy, ensuring minimal disruption to print process. Modified ZMorph© printer is able to print accurately with 4 inch long needle.

← View all Capstone Projects