From Porsche to your pocket: bringing carbon fiber to the masses

Team: Paul Ceralde (MSE), Arnaud Dyen (ME), Harsh Raj Chauhan (ME), Juan Pablo Viaux (ME), Michelle Satkin (IEOR), Somsakul Sombon (IEOR)

Advisors: Scott Perkins (Arris Composites), Matthew Sherburne (MSE)

In 1855, a process for inexpensively manufacturing aluminum was developed, and the price dropped from $500 to $40 per kilogram in just 5 years. This process transformed aluminum from a metal reserved for royalty into the ubiquitous material we know today. Arris Composites, a Berkeley-based startup, has developed a process that could do the same for carbon fiber. Currently, manufacturing aligned composites is expensive and reserved for Bugatti’s and Boeing Dreamliners. Arris’ new manufacturing technique could significantly reduce the price of carbon fiber and make it a viable material for a host of new applications. This project aims to answer some of the questions raised by the development of this technology. Where could this material be used, would it be designed differently and how would it perform relative to current materials?

Exploration

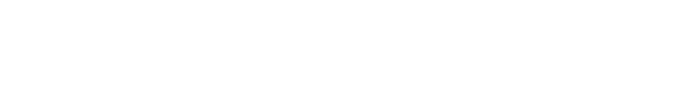

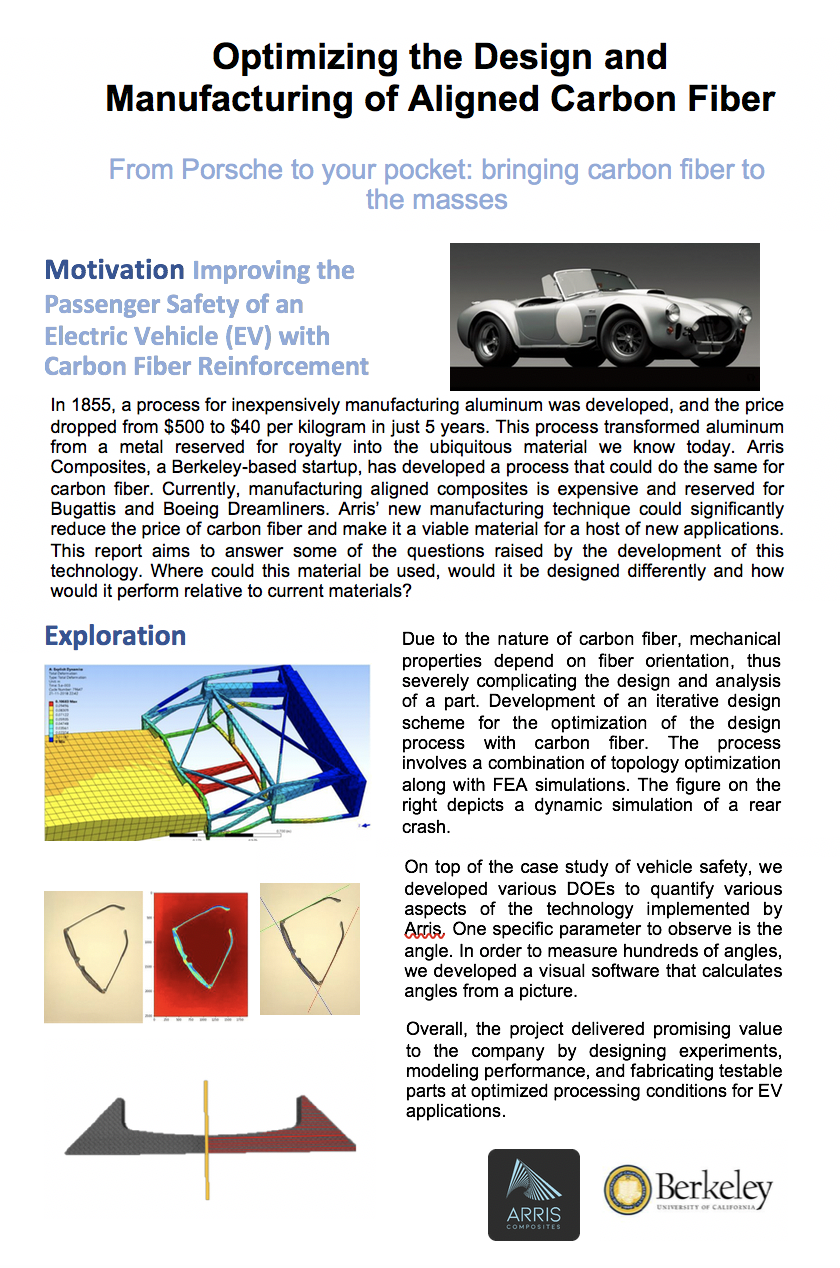

Due to the nature of carbon fiber, mechanical properties depend on fiber orientation, thus severely complicating the design and analysis of a part. Development of an iterative design scheme for the optimization of the design process with carbon fiber. The process involves a combination of topology optimization along with FEA simulations. The figure on the right depicts a dynamic simulation of a rear crash.

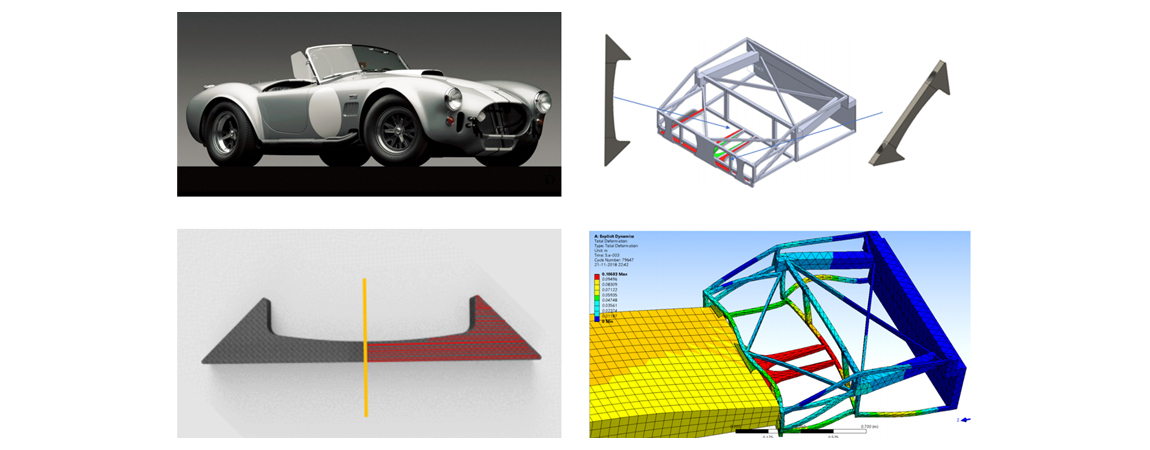

On top of the case study of vehicle safety, we developed various DOEs to quantify various aspects of the technology implemented by the Arris. The IP developed by Arris allows to control the interior of the parts manufactured. One specific parameter to observe is the angle. In order to measure hundreds of angles, we developed a visual software that calculates angles from a picture.

Overall, the project delivered promising value to the company by designing experiments, modeling performance, and fabricating testable parts at optimized processing conditions for EV applications.

Project Brief

← View all Capstone Projects