Unleash the true potential of smart glasses leveraging an affordable chemical process

Team: Xianxin Zhang (ME), Yue Meng (MSE), Yueming Li (MSE), Zhuokai Xian (MSE)

Advisors: Junqiao Wu (MSE)

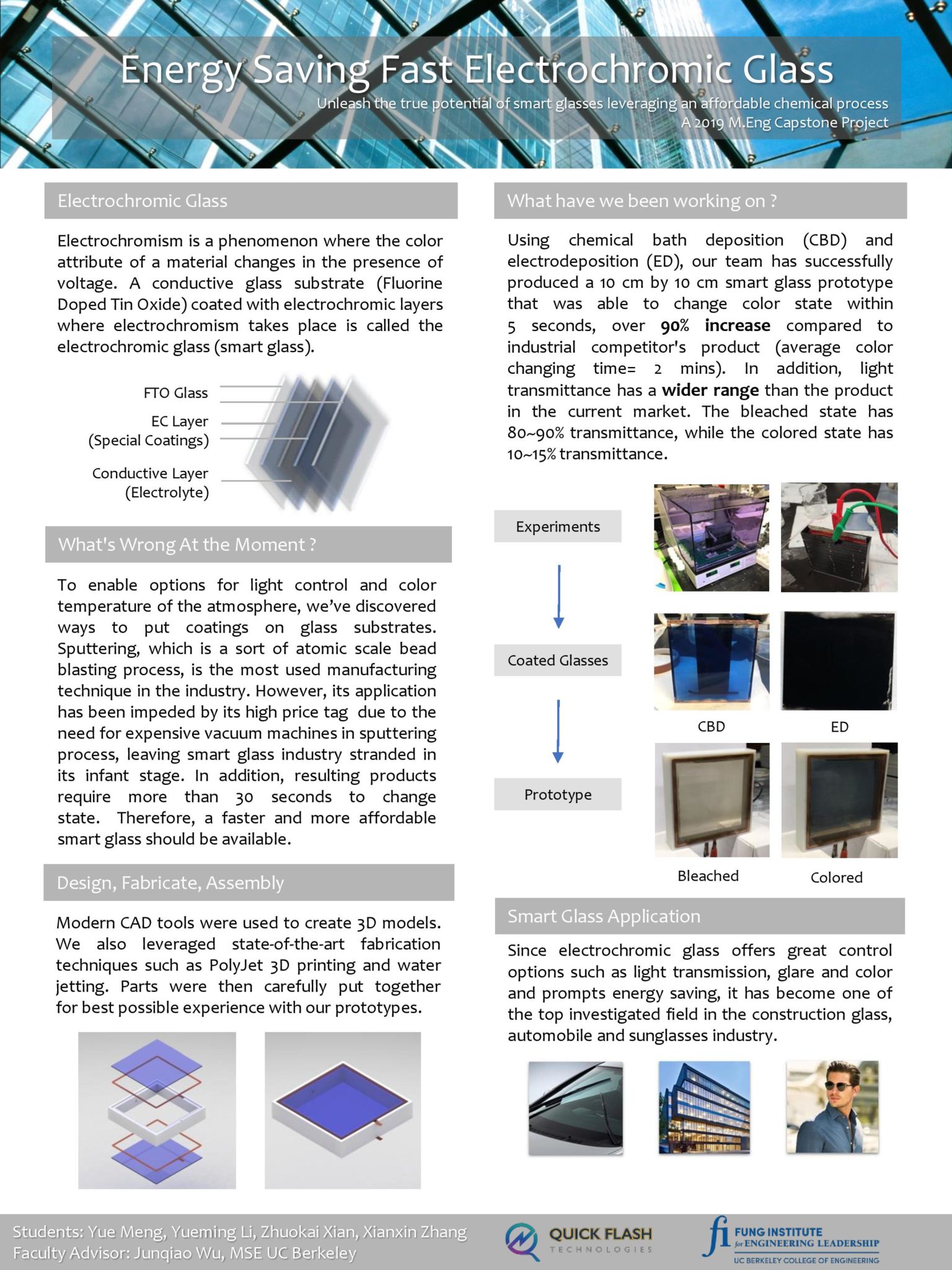

Electrochromic (EC) coating is one of the ways to alter glass attributes through the application of voltage on conductive layers. However, current manufacturing processes for such glass aren’t optimized and required high-end equipment resulting in high price tag for the product. To make it more accessible, this capstone project approaches from an unconventional angle. Instead of inventing new glass products, a better alternative to the sputtering process called chemical bath deposition (CBD) has been utilized for fabrication at Berkeley. To date, with the help of many specially tuned processes, customized equipments and tools, a 10cm by 10cm glass prototype has been successfully developed employing the CBD process proving that the approach is indeed inexpensive and accessible.

Electromagnetic Glass

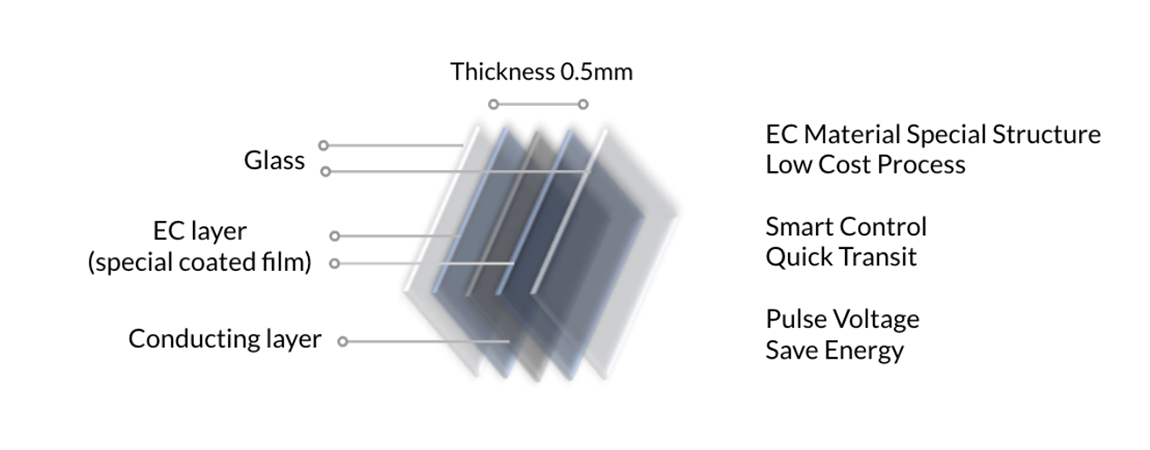

Electrochromism is a phenomenon where the color attribute of a material changes in the presence of voltage. A conductive glass substrate (Fluorine Doped Tin Oxide) coated with electrochromic layers where electrochromism takes place is called the electrochromic glass (smart glass).

Problem

To enable options for light control and color temperature of the atmosphere, we’ve discovered ways to put coatings on glass substrates. Sputtering, which is a sort of atomic scale bead blasting process, is the most used manufacturing technique in the industry. However, its application has been impeded by its high price tag due to the need for expensive vacuum machines in sputtering process, leaving smart glass industry stranded in its infant stage. In addition, resulting products require more than 30 seconds to change state. Therefore, a faster and more affordable smart glass should be available.

Process

Modern CAD tools were used to create 3D models. We also leveraged state-of-the-art fabrication techniques such as PolyJet 3D printing and water jetting.

Solution

Using chemical bath deposition (CBD) and electrodeposition (ED), our team has successfully produced a 10 cm by 10 cm smart glass prototype that was able to change color state within 5 seconds, over 90% increase compared to industrial competitor’s product (average color changing time= 2 mins). In addition, light transmittance has a wider range than the product in the current market. The bleached state has 80~90% transmittance, while the colored state has 10~15% transmittance.

Applications

- Construction Glass

- Automobiles

- Sunglasses

← View all Capstone Projects