As 3D printing technology becomes increasingly more important, users’ demand for 3D printing material has also become more complex. The team designed and produced a newly-fashioned 3D printing filament material (PLA + Carbon Fiber) at a lower overall operational cost with sustainability and also developed the industrial application of this new material.

Team: Johann Chow , Xiao Liu , Nagapratik Mundla, Jiayun Shao, Apoorva Sooranahalli, Tsung-Ying Tsai

Problem:

The current filament’s material properties would not suffice the needs of most users.

Users:

- Industrial manufacturers

- Research Institutes / Students

- Artists

Why 3D printing?

- Good for comparing and prototype

- Fast to print

- Easier to test new ideas

Our goal is to create new 3D printer materials that have properties that are determinable by customers that has better mechanical properties, is low-cost, and time-efficient.

User Interview

The result of 60+ such user interviews: wearability and stress.

Q: What would you like to print with the material having no limits?

A: I would like to print more functional parts like a gearbox if I can have stronger printing materials. PLA is too soft.

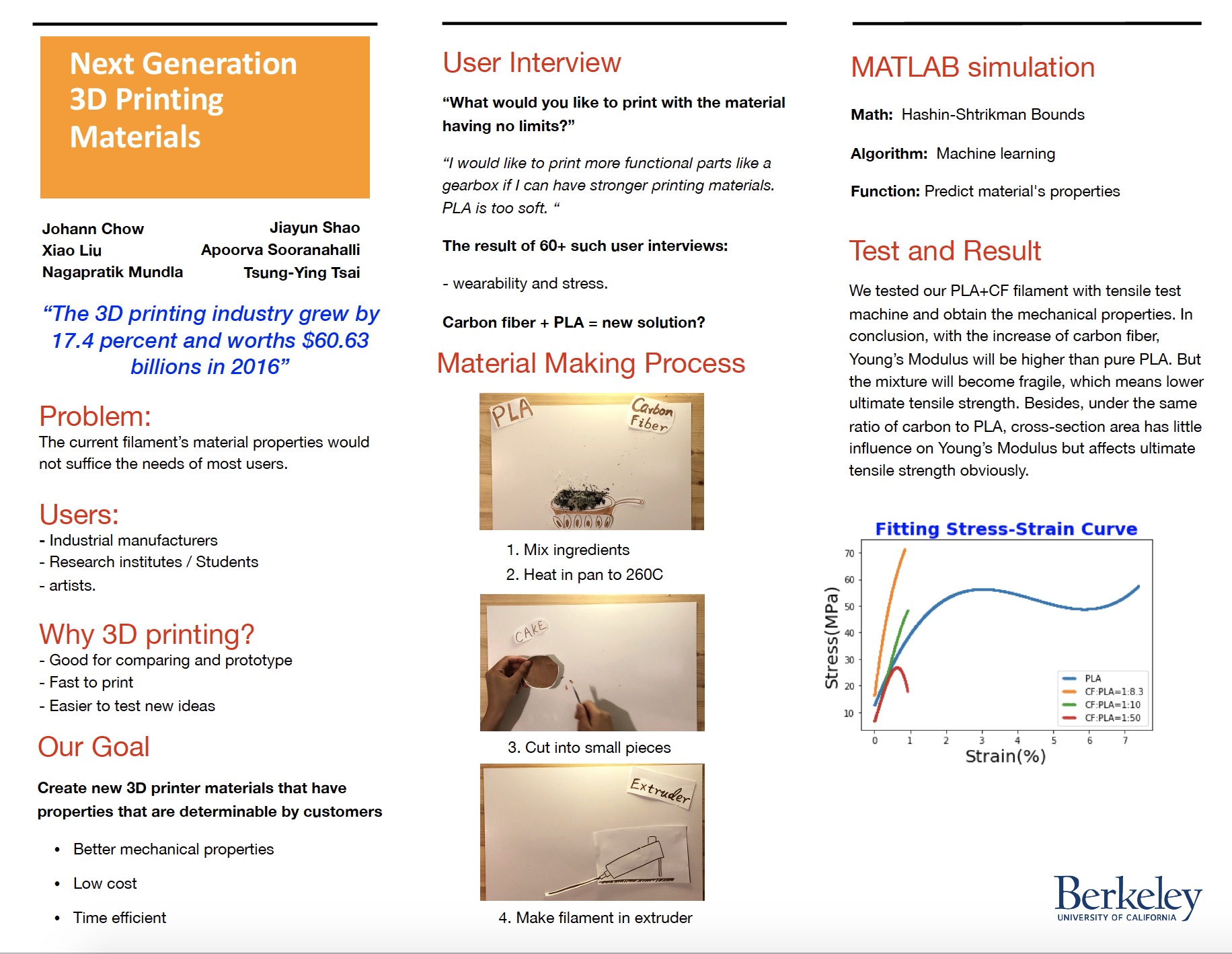

MATLAB simulation

- Math: Hashin-Shtrikman Bounds

- Algorithm: Machine learning

- Function: Predict material’s properties

Test and Result

We tested our PLA+CF filament with tensile test machine and obtain the mechanical properties. In conclusion, with the increase of carbon fiber, Young’s Modulus will be higher than pure PLA. But the mixture will become fragile, which means lower ultimate tensile strength. Besides, under the same ratio of carbon to PLA, cross-section area has little influence on Young’s Modulus but affects ultimate tensile strength obviously.

The 3D printing industry grew by 17.4 percent and worths $60.63 billions in 2016.

← View all Capstone Projects