Team: Stu Burgess (ME), Mubasheer Chombakkadath (NE), Yong Mok Kim (NE), Juhi Nandwani (NE), Richy Rocha (NE), Tatiana Siaraferas (NE), Madeleine Waller (NE)

Advisor: Massimiliano Fratoni (NE)

Nuclear fission creates many rare elements that are not normally found in nature and are discarded in traditional reactor fuels. These rare elements are useful for many industrial and medical processes, such as thickness gauging and cancer treatments. Our team is designing a new generation molten salt nuclear reactor with a sole focus on continuous production and extraction of these elements without the risk of nuclear weapons proliferation. We aim to provide an innovative and safe approach to meet current US demands at or below market pricing.

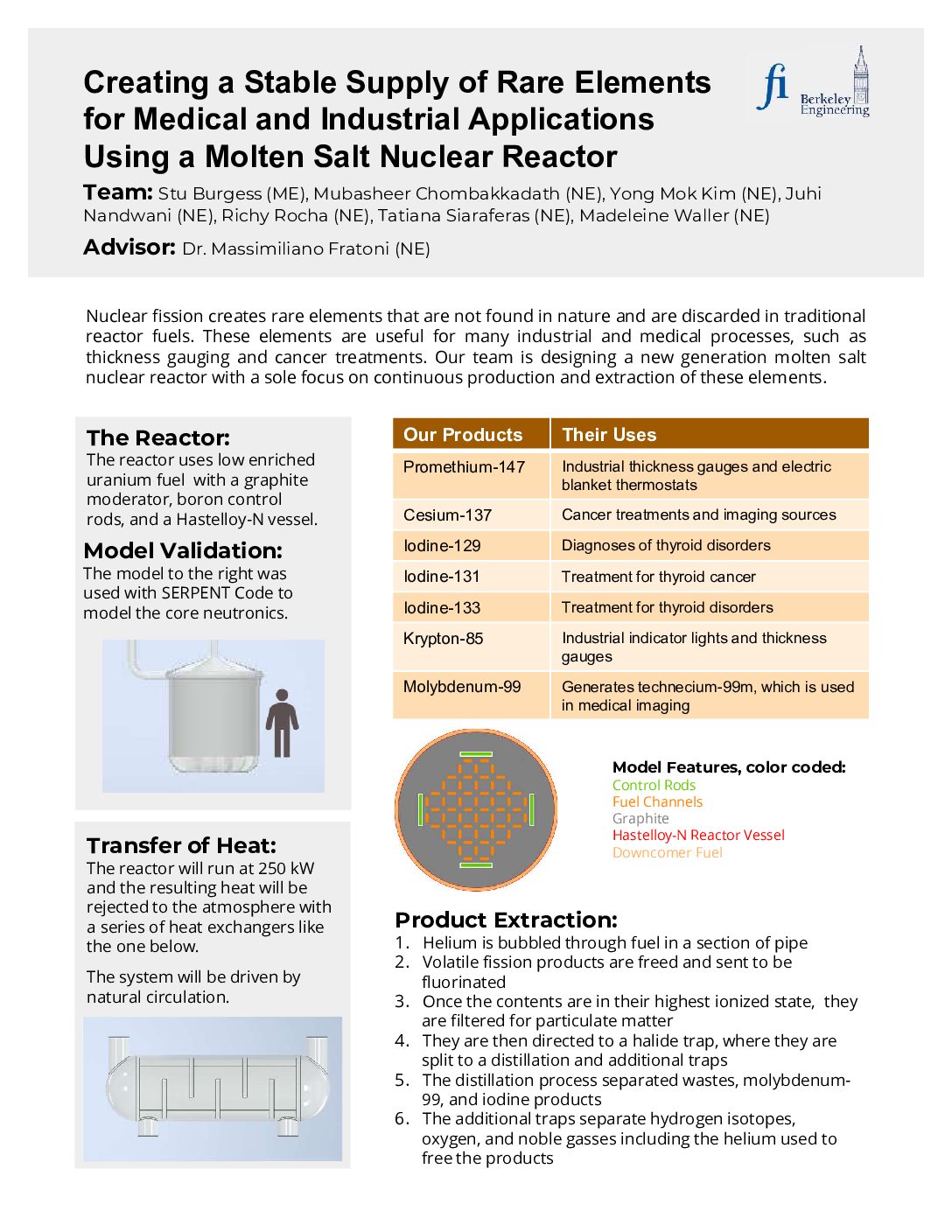

Reactor:

The reactor uses low enriched uranium fuel with a graphite moderator, boron control rods, and a Hastelloy-N vessel.

Model Validation:

The model to the right was used with SERPENT Code to model the core neutronics.

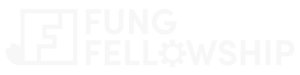

Transfer of Heat:

The reactor will run at 250 kW and the resulting heat will be rejected to the atmosphere with a series of heat exchangers like the one below. The system will be driven by natural circulation.

Product Extraction:

- Helium is bubbled through fuel in a section of pipe

- Volatile fission products are freed and sent to be fluorinated

- Once the contents are in their highest ionized state, they are filtered for particulate matter

- They are then directed to a halide trap, where they are split to a distillation and additional traps

- The distillation process separated wastes, molybdenum-99, and iodine products

- The additional traps separate hydrogen isotopes, oxygen, and noble gasses including the helium used to free the products

← View all Capstone Projects